By Admin

By Admin Preventing blockages in drip irrigation pipelines, especially when using organic fertilizers or hard water, requires proactive maintenance and careful management. Here are some strategies to help mitigate blockages:

Filtration: The effective filtration of irrigation water is paramount in preventing blockages within drip irrigation systems, particularly when faced with the challenges posed by organic fertilizers and hard water. Employing a multi-stage filtration approach, beginning with coarse screen filters followed by finer disc filters, ensures comprehensive removal of debris, sediment, and particulate matter. Regular maintenance of these filters is essential, involving systematic cleaning or replacement to uphold optimal filtration efficiency. Consider the installation of backup filters or bypass mechanisms to minimize system downtime during maintenance activities.

Flush the System: Systematic flushing serves as a proactive measure to purge irrigation lines of accumulated sediments, mineral deposits, and organic residues, safeguarding against potential blockages and optimizing water flow rates. Develop a robust flushing protocol tailored to the specific characteristics of your irrigation system, incorporating scheduled flushing cycles based on factors such as water quality, usage patterns, and environmental conditions. Implementing automated flushing mechanisms or programmable flush valves streamlines the flushing process, ensuring thorough cleansing without disrupting regular irrigation operations.

Use Chemical Treatments: Chemical treatments offer an effective means of mitigating mineral scaling and organic buildup within drip irrigation pipelines, thereby enhancing system longevity and performance. Select specialized treatment formulations containing corrosion inhibitors, dispersants, and scale inhibitors tailored to the prevailing water chemistry and anticipated contaminants. Implement a comprehensive treatment regimen encompassing periodic application of treatment solutions, followed by thorough system flushing to remove dissolved residues and restore optimal water quality.

Water Quality Testing: Rigorous water quality testing provides critical insights into the composition and characteristics of irrigation water, empowering proactive management of potential risk factors associated with blockages in drip irrigation systems. Employ advanced analytical techniques, including spectroscopy, chromatography, and titration, to assess key parameters such as pH, alkalinity, hardness, and mineral content. Establish a robust sampling protocol encompassing regular water sampling at strategic points within the irrigation network, supplemented by laboratory analysis or on-site testing using portable instrumentation. Utilize comprehensive water quality data to inform strategic decisions regarding water treatment, filtration optimization, and overall system management.

Proper Fertilizer Application: Precision application of organic fertilizers is essential to prevent the introduction of undissolved solids and particulates into drip irrigation pipelines, mitigating the risk of blockages and ensuring optimal nutrient delivery to plants. Adopt best practices for fertilizer preparation, including pre-dissolution in water or incorporation into soil amendments to facilitate uniform distribution and minimize potential clogging. Implement sophisticated injection systems equipped with precise dosing controls and mixing chambers to achieve accurate fertilizer application rates tailored to the specific requirements of each irrigation zone.

Maintain Adequate Pressure: Maintaining optimal pressure levels within drip irrigation systems is critical to ensuring uniform water distribution and mitigating the risk of blockages caused by pressure differentials or hydraulic instability. Employ precision pressure regulation devices, including pressure regulators, control valves, and pressure-compensating emitters, to stabilize system pressures and prevent excessive fluctuations that may exacerbate blockage formation. Conduct regular hydraulic modeling and system analysis to optimize pressure settings and hydraulic design parameters, accounting for variations in elevation, friction losses, and flow dynamics across the irrigation network.

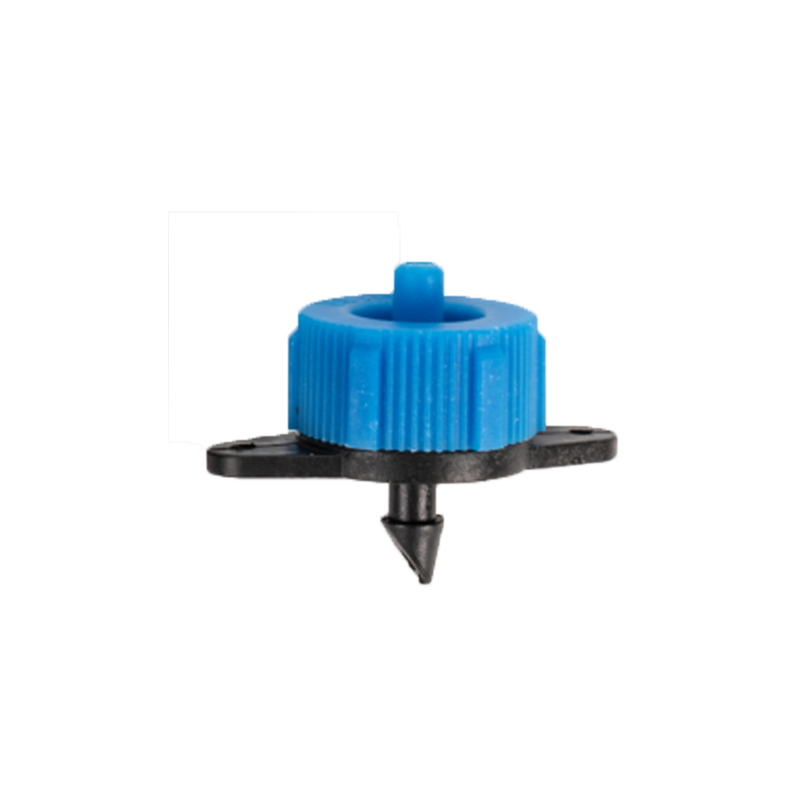

YR9818A irrigation dripper